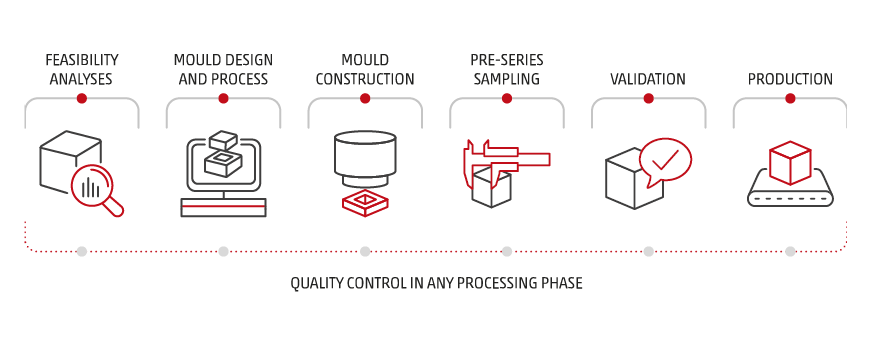

Internal personnel, with consolidated engineering and technological skills, perform feasibility analyses for the design and manufacture of the moulds, pre-series sampling, mechanical machining, special finishes using the most modern design tools and a range of latest generation numerical control machines.

This expertise is the result of a systematic approach founded on the highest quality standards, strict validation procedures, and process analyses. Campress certifies the compliance of every item produced based on the specifications of the client, in addition to providing complete traceability.

Machine range

| Department | Quantity | Machines range |

|---|

| Mould design | 4 machining centres, 2 turning centres | Mechanical workshop with CNC machines |

| | 4 | Vertical automatic warehouses for mould storage. |

| Cutting | 14 | Latest generation numerical control sawing machines. |

| Graphite coating | 2 | Graphite coating machines |

| Stamping | 16 | Mechanical presses from 200 to 550 tons. |

| Shearing | 8 | Rotary table shearers, 3 of which with automatic loading. |

| Sandblasting | 2 | Shot blasting machines (automatic tumbling belt systems with steel or brass shot). |