Our expertise in all supply chain processes allows us to supply finished products: in addition to the casting process, we also carry out machining, treatments and surface finishes.

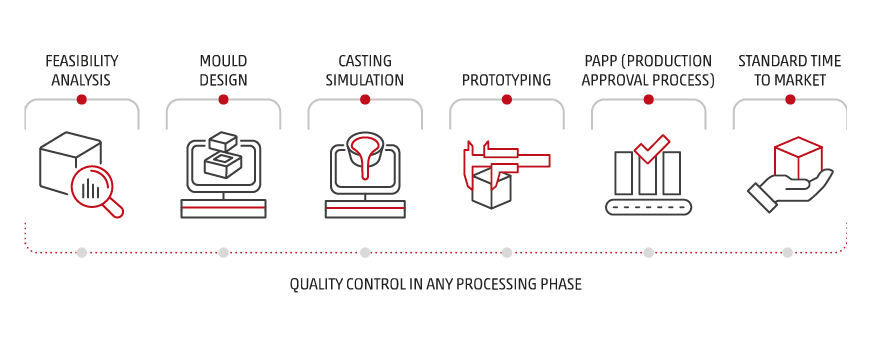

Through 3D design SW (PRO-E) and simulation SW (PRO CAST) we guarantee perfect casting even for components with the most complex design. Our laboratories are equipped for metallurgical, dimensional and structural checks of castings using X-Ray devices.

Machine range

| Department | Quantity | Machines range |

|---|

| Melting centre | 5 | Crucible melting furnaces |

| Foundry department | 8 | 8 automatic moulding machines opening 1,200 - 1600 mm. with Cartesian robot |

| | 4 | 4 stand-by furnaces with different loading capacities |

| Finishing department | 1 | Trebi automatic cutting machine |

| | 2 | Manual cutting machines |

| | 2 | Automatic cutting machines |

| | 1 | Cluster sandblaster |

| | 1 | Deburring bench |

| Mechanical workshop | 1 | Comev lathe |

| | 1 | C.B. Ferrari vertical centre |

| | 1 | Idra MV850 vertical centre |

| | 1 | Moulds sandblasting machine with rotary table |

| Macchine di misura | 1 | Gilardoni X-ray machine |

| | 1 | NGR Quantometer |

| | 1 | COORD3 three-dimensional measuring machine |

| | 1 | Durometer |

Fonderie Mora Gavardo Whistleblowing

Fonderie Mora Gavardo Policy Whistleblowing