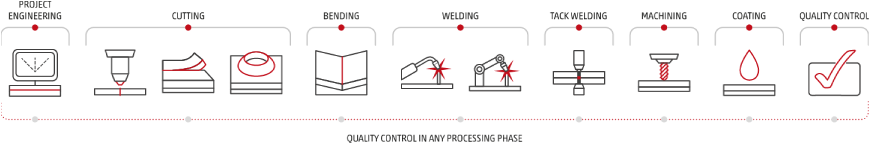

We offer consolidated skills in the sheet metal working process, both from a technological and functional point of view, to create customized solutions.

We use cutting-edge software and management methods, as well as the latest generation machine range. The physical flow of production starts from the automatic warehouse in which sheets are stocked. The sheets then transit through the cutting department, which is equipped with laser, plasma and punching systems.

The cut sheets continue towards the bending department, which is alongside the stations dedicated to welding (both manual and automatic), to tack welding and to mechanical processing.

Machine range

| Department | Quantity | Machines range |

|---|

| Cutting | 2 | Amada laser systems with automatic loading-unloading storage unit |

| | 1 | Amada punching machine equipped with automatic loading-unloading storage unit |

| | 1 | Amada semi-automatic shear |

| Bending | 3 | Amada / Schiavi folding machines |

| | 1 | Sergi bending machine |

| Welding | 9 | Manual mig, mag and tig welding stations |

| | 1 | Tiesse mig, mag and tig welding robots (max. workpiece dimensions: 4500 x 1500 x 1000 mm) |

| Spot welding | 2 | Tecna spot welders |

| | 1 | Tecna multiple spot welder |

| Mechanical machining | 1 | Tiger vertical-horizontal milling machine |

| | 1 | PBR manual lathe |

| Painting and treatment | 1 | Munari epoxy powder painting system |

| | 1 | Trivalent phosphodegreasing washing system (cast iron, steel, aluminium) |